Crucial Overview to Strapping Machine Repair: Making Sure Optimum Performance and Long Life

Strapping machines play a crucial duty in product packaging and logistics. Nevertheless, they can run into numerous issues that hinder their performance. Understanding these common troubles and their hidden reasons is essential for efficient fixing and maintenance. Proper diagnostics and routine maintenance can expand an equipment's life-span substantially. Yet, lots of operators neglect crucial maintenance steps. What are the most effective techniques for making sure these machines operate at peak effectiveness? The responses might amaze you.

Typical Strapping Machine Issues and Their Causes

Strapping machines are important for efficient packaging operations, they can encounter different problems that interrupt operations. Common issues include misfeeds, where the strap does not feed properly through the machine, frequently triggered by inappropriate alignment or used components. One more frequent concern is band breakage, which can arise from utilizing the wrong kind of band or too much stress during the strapping procedure. Furthermore, irregular seal strength may occur because of insufficient warmth or stress setups, causing weak or malfunctioning seals. Dust and debris build-up can also trigger mechanical failings, hindering the device's efficiency. Operators may additionally experience electrical breakdowns, such as damaged sensing units or control failures, which can halt production. Identifying these concerns and their hidden reasons is important for keeping ideal performance and guaranteeing the longevity of strapping machines in packaging procedures.

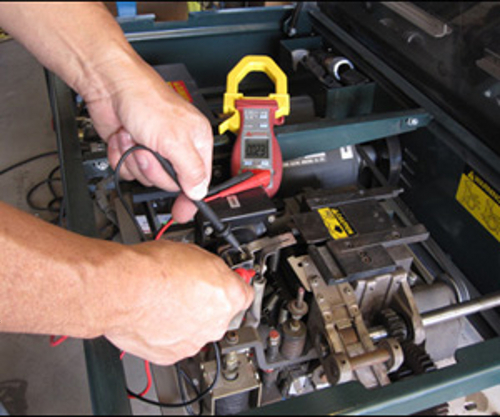

Important Tools for Strapping Machine Repair

Attending to the usual problems that strapping machines come across requires the right tools to ensure effective fixings and maintenance. Important devices consist of pliers, screwdrivers, and wrenches, which are important for taking apart and rebuilding parts. A multimeter is essential for identifying electrical issues, allowing professionals to determine damaged links or components. Furthermore, a torque wrench guarantees that bolts are tightened to the producer's specs, preventing future breakdowns. Lubricating substances and cleansing supplies are necessary for normal upkeep, assuring smooth procedure and longevity of the machine. Substitute components, such as sensing units, electric motors, and belts, should also be on hand to assist in quick repair services. An extensive repair service manual offers important guidance, aiding professionals browse the complexities of strapping equipment fixing efficiently. Using these tools successfully can greatly improve the performance and lifespan of strapping machines, lessening downtime and operational interruptions.

Step-by-Step Troubleshooting Overview

Just how can professionals efficiently identify and deal with issues with strapping machines? A methodical strategy is vital. Initially, they must recognize the signs, such as irregular strapping or equipment jams. Next off, technicians should review the customer manual for certain error codes or fixing steps connected to the observed issues.

Once signs and symptoms are kept in mind, they need to check the device's elements, including the tensioner, sealing head, and feed system for wear or damages. It is very important to examine for correct positioning and any blockages. After visual evaluations, professionals must examine the electric links and sensors to assure they are operating appropriately.

If problems linger, doing a functional examination after each change will aid separate the issue. Documenting each step taken is very important for future referral. Following this organized troubleshooting overview permits specialists to successfully pinpoint the issue and execute efficient repair services, thereby boosting device dependability and performance.

Preventative Upkeep Tips for Durability

Carrying out a robust preventative maintenance plan is essential for ensuring the long life of strapping machines. Regular inspections need to be performed to identify any kind of indications of wear or damage, focusing on essential components such as belts, rollers, and sensing units. strapping machine Recommended Site repair. Cleaning the machine frequently helps avoid debris accumulation, which can cause operational concerns. Lubrication of relocating parts is necessary; utilizing the supplier's advised lubricants assurances smooth procedure and decreases friction

Furthermore, operators must keep an eye on the machine's efficiency metrics, keeping in mind any kind of abnormalities that might indicate possible troubles. Keeping a thorough maintenance log help in tracking service background and organizing timely treatments. Training personnel on proper use and handling can markedly decrease the danger of operator-induced damages. Lastly, replacing used elements proactively, rather than reactively, can reduce downtime and extend the equipment's life expectancy. Complying with these preventative maintenance ideas will certainly contribute to ideal efficiency and toughness of strapping machines.

When to Look For Specialist Aid

Furthermore, when parts show signs of wear or damage, professional assessment ends up being vital to guarantee security and functionality. Seeking assistance from experienced service technicians is a good idea if internal maintenance team lack the experience or tools to detect complex issues. Regular examinations with professionals can likewise aid in identifying prospective troubles prior to they intensify. Eventually, timely treatment by professionals not only prolongs the life-span of the equipment but likewise safeguards productivity, ensuring that operations continue to be smooth and reliable.

Often Asked Concerns

How Typically Should I Change the Strapping Machine's Components?

Strapping device parts need to be changed every 1-3 years, depending on usage and wear (strapping machine repair). Regular evaluations and maintenance can help recognize parts requiring substitute earlier, making sure excellent capability and minimizing the threat of unanticipated failures

Can I Use Various Strapping Products With My Machine?

Various strapping materials can commonly be made use of with a maker, provided they satisfy certain dimension and stress requirements. Nevertheless, compatibility must be validated to assure peak efficiency and prevent potential damage or malfunction.

What Are the Indicators of an Overheating Strapping Machine?

Signs of a getting too hot strapping equipment consist of unusual noises, constant shutdowns, too much warmth emanating from elements, smoke, and irregular strapping quality. Prompt identification of these symptoms is important for avoiding damage and guaranteeing effective procedure.

How Can I Improve Strapping Rate Without Sacrificing High Quality?

To improve strapping rate without sacrificing top quality, one can optimize device settings, make use of high-quality materials, maintain equipment frequently, and train operators in reliable methods, guaranteeing a balance Find Out More in between rate and efficient strapping efficiency.

Are There Certain Brands Known for Better Sturdiness?

Certain brand names, such as Signode and Mosca, are renowned for their durability in strapping machines. Their durable construction and top notch products usually result in extended life-spans and dependable performance in demanding industrial settings.

How can service technicians successfully identify and resolve issues with strapping machines? They should recognize the signs and symptoms, such as inconsistent strapping or machine jams. Implementing a durable preventative maintenance strategy is crucial for assuring the longevity of strapping machines. Various strapping products can commonly be made use of with a device, offered they fulfill certain dimension and tension demands. Indicators of an overheating strapping machine consist of uncommon noises, frequent closures, extreme warm emanating from components, smoke, and irregular strapping top quality.